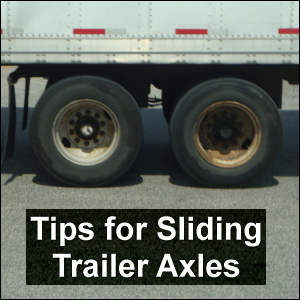

Have you ever needed to slide your trailer axles to make your axle weights legal — especially when a very heavy load is on board — and they seemed impossibly stuck?

Before you call a service truck, you might consider (if they are approved by your trucking company) trying Mike’s tips…

Before you call a service truck, you might consider (if they are approved by your trucking company) trying Mike’s tips…

Rusted Axles?

First, if the trailer is older, there’s a good chance that the track that the tandems slide on is rusted.

They may just need a really good coat of lubricant on them, like one of these two products, as listed from Amazon.com, with which we have an affiliate relationship.

WD-40 Lubricant, Aerosol Can with Smart Straw, 12 Fluid Ounces

Blaster 16-PB Penetrating Catalyst – 11 oz.

In the past, we have used WD-40 or Penetrating Blaster to help loosen seemingly stuck trailer axles.

(Vicki thinks that the scent of the Penetrating Blaster lingers longer, but that if it is used exclusively outside, it isn’t so bad.)

Both of these lubricants are very good at what they are advertised to do.

See if the application of lubricant will loosen up the trailer axles on the track.

Rock the Trailer

Second, Mike has tried (from within the tractor) to rock the trailer to loosen the axles.

Sometimes this works, but if the tandems are really stuck, he ramps up the trailer axles unsticking procedure…

Use Chocks

Third, you know that various shippers and receivers use a variety of tools to help hold trailers in dock.

Among them are chocks…

This photo shows three docks where rubber chocks are used to help prevent trailers from being moved.

This photo shows three docks where rubber chocks are used to help prevent trailers from being moved.

At this dock, a metal chock is used to help prevent trailers from being moved.

At this dock, a metal chock is used to help prevent trailers from being moved.

These are close-up (albeit a bit blurry) photos of chocks: a rubber chock on the left and two different views of a metal chock.

These are close-up (albeit a bit blurry) photos of chocks: a rubber chock on the left and two different views of a metal chock.

Chock Placement

In this photo, professional driver Mike Simons looks at the placement of a chock in front of the tires of a trailer backed in front of a dock.

In this photo, professional driver Mike Simons looks at the placement of a chock in front of the tires of a trailer backed in front of a dock.

(Note: The trailer stand shown in the foreground is not used to help move axles. Rather, a trailer stand is used to stabilize the nose of a trailer so that it won’t tip forward when a forklift is driven into it when loading or unloading the product.)

If the lubricant and rocking of the trailer don’t work to free the trailer axles, Mike will place a pair of chocks either behind or in front of the tires (depending on where the axles are) to help give enough traction to loosen the axles.

We’ve never seen chocks for sale at a truck stop, but you can buy them online.

Using chocks always worked for Mike (even if they initially slid) — up until the day that he picked up a heavy load of bottled water on an old trailer where the tandems were badly rusted.

That meant ramping up yet again…

Trailer Brakes

Fourth, check to see if in trying to slide your tandems that the trailer brakes are holding.

You may need to make an adjustment (and we trust that you learned how to use a 9/16″ wrench or crescent wrench to do that when you went through training).

Just make sure that if you need to really tighten the brakes to keep them from moving, you set them where they need to be for travel before leaving.

There’s no sense in leaving them too tight for travel and smoking your brakes going down the road…!

If the brakes were the problem and you adjusted them, try sliding your axles again.

Note: Only those who are “certified” to adjust brakes are supposed to do this.

Curb Power

Fifth, after trying all of the above and finding that the trailer axles absolutely would not move, Mike had to back up to a curb like this one.

If you need to use a curb to adjust your trailer axles, make sure that you use one that is high enough to keep you from rolling over the top of it.

If you need to use a curb to adjust your trailer axles, make sure that you use one that is high enough to keep you from rolling over the top of it.

Perhaps you can’t see it really well, but the curb in this photo is not much more than a foot away from a steep embankment!

Note: Using one of the moveable concrete curbs may not be a good idea as they can (obviously) be moved out of place. Using a fixed curb is much better for this kind of thing.

![]() Money saving tip: While we do not guarantee that using any or all of these tips will solve a specific problem with a specific trailer, we have found that following them in the order listed can help avert calling a service truck to move trailer axles.

Money saving tip: While we do not guarantee that using any or all of these tips will solve a specific problem with a specific trailer, we have found that following them in the order listed can help avert calling a service truck to move trailer axles.

If you need to enlist the help of another driver in making adjustments, please don’t let your pride stand in your way.

Always observe safety when working around or under your trailer.

Never ever attempt to move a set of axles when someone is under the trailer, as this can lead to a fatal accident.

There are some trailers, frankly, that need to be retired.

If you encounter one, don’t hesitate to let your company know.

Perhaps it just needs more maintenance than you can supply with the tools and equipment you have at your disposal.

Return from Sliding Trailer Axles: What To Do When Tandems Are “Stuck” to our Tricks of the Trade page or our Truck Drivers Money Saving Tips home page.